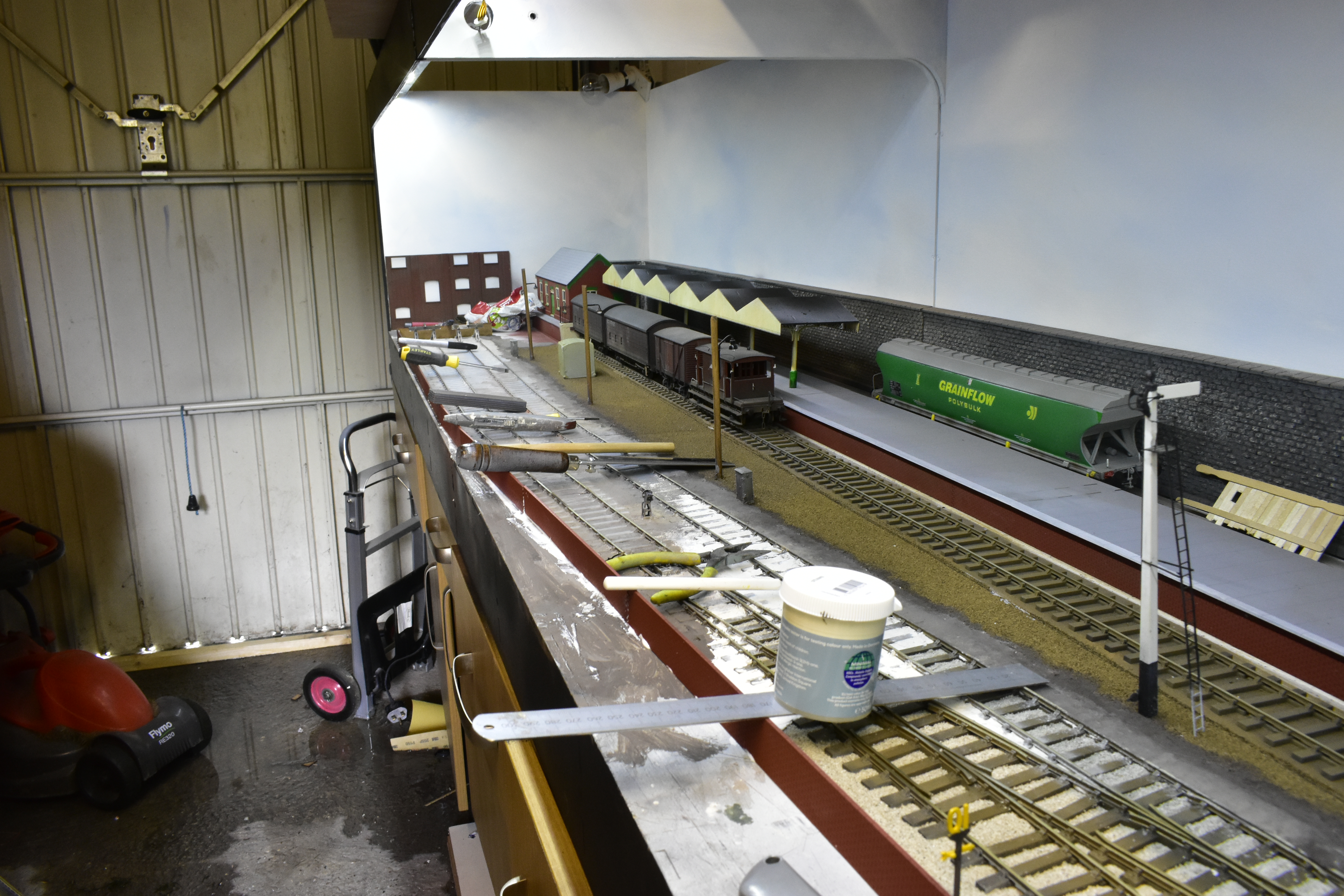

If there was a train doctor, this is what I would tell him! I’ve tried taking the tablets, using certain colours even doing a bit more work but many parts of the layout are at the scenic but messy stage and it’s not getting much better yet. This is a stage we all have to go through but not many people share this. SO, I’m going to be brave. Please be gentle, it won’t always be like this.

Last time we left our long sidings looking pale and not really oily and at the end of their days. So below is how we left them…

The above picture shows that we now have a little more colour, but not nearly enough yet and the track shows no signs of being weathered. I shall do this when all the ballasting is done.

I will use lots of browns, black, oil spots, puddles and static grass, however, in my eagerness I started to focus on an an area down the other end, the coal yard.

I chose to stick some cork down to raise the height and save a bit of ballast and/or clay, however, in hindsight, I should have put foam board around the lot and skipped the ballast stage.

Despite the warmth in recent days the glue took ages to dry and I hate waiting for things to dry. Once the ballast was dry, I started to put chunks of DAS clay into the ballast, pushing it in with my fingers.

This is the scene after the forground is covered in DAS clay and a start made at the back. When, I’m done, I stipple the clay with a stiff one inch brush which gives the clay a nice rough surface and hides all the joins from all the pieces.

The whole are is now covered and I’ve run a vehicle over the clay so some tyre marks will be present in the muddy ground. I also pushed my finger in hard in one spot so I can create a nice large puddle. The area will have piles of coal, coal sacks and a coal merchant’s hut. I’m really looking forward to this little bit of gritty history.

I was tempted to make one of these crossings with coffee sticks but when someone has made such a lovely job of these, why would you bother. Cutting the angle sections was fun though.

I’ll keep on ballasting, then I hope we’ll have something that starts to look like a proper railway!

Come back soon!

Shaun