Well having built got so many of these laser cut models from https://www.lasercutrailwaymodels.co.uk/O-Gauge-7mm, I’m starting to feel that I need to make some more progress with the factory units.

They really are good value and go together really well and I would certainly recommend them to anyone.

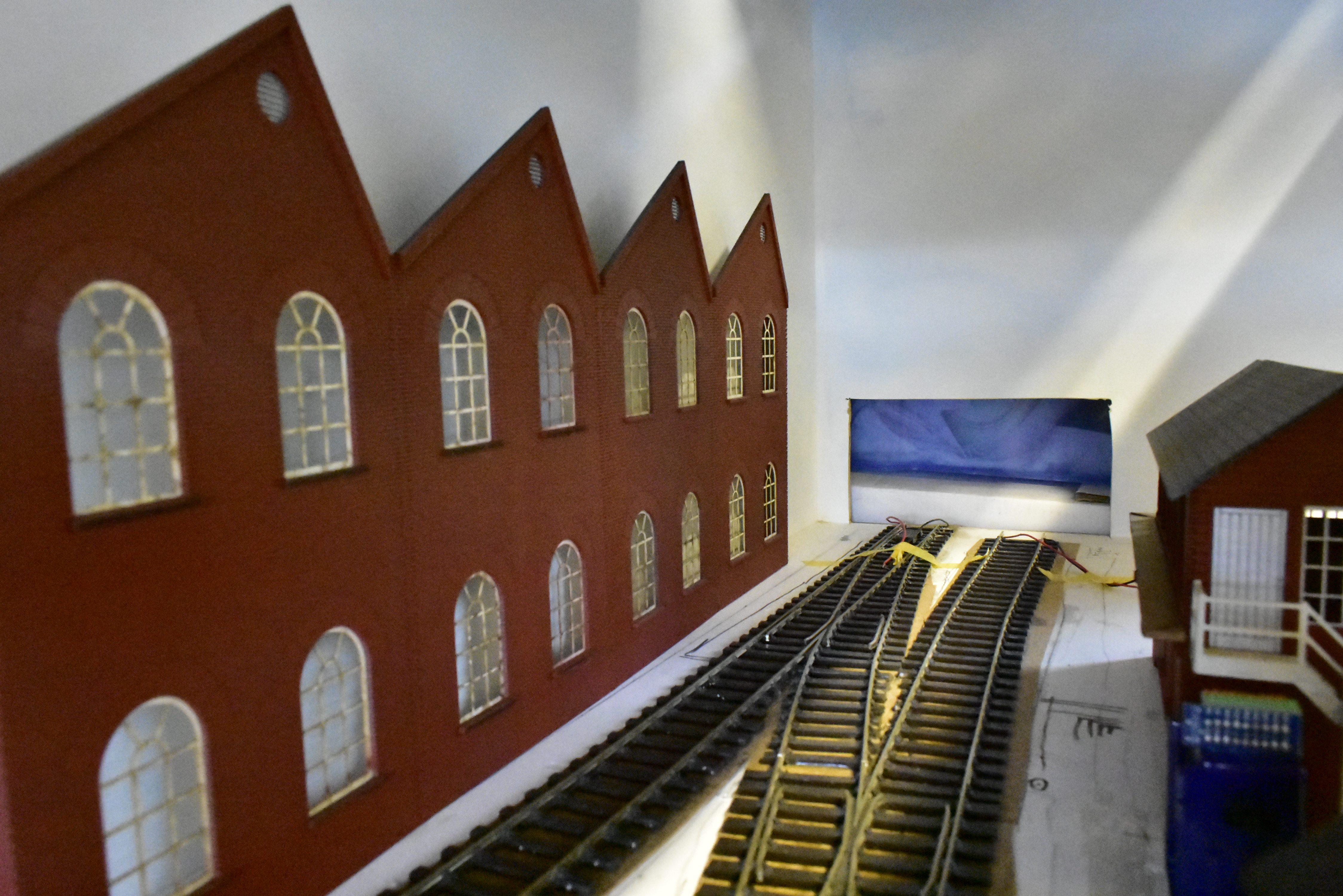

The factory units shown below where built around the country in vast quantities and the design was very common for railway buildings and industrial buildings. The models are supplied as low relief models with one roof section being solid and the other having windows that would allow the light through. As I said in a previous posting, the placing of the track meant that I had to make the factory narrower than planned. As luck would have it, reducing the width of all the roof parts was made easier because the laser cutting design has inscribed some lines onto the roof lines and I used one of these lines as a cutting guide.

I shall have some sections almost flush to the rear scenic board and then the remaining boards wlll come forward about 15mm providing a small change and a little visual interest. I’ve now started to add all the roof sections on and will make sure that the rain strip or gutting and down pipes are inserted between the sections.

The sections that are flush to the back board will also cross the baseboards with one factory piece on board No. 2 and then the rest on board No. 3. The kits include a laser cut gutter piece, however, I will add my own guttering made from Evergreen pipe or some other similar brand of plastic pipe. I’m not sure how I will do this across the baseboard join for one of the down pipes but that will be a problem for another day!

The roof sections will soon need to be glazed and this is included in the kit, however, before I do this, I will probably paint the window frames again as they are a bit grubby and they do get discoloured by the heat from the laser cutting process. The window sills need to be painted too and the factory units will benefit from some weathering before they are fixed in place.

I’m not sure if I should drill a few holes in the back scene to push in a few little lights tp light up the factory here and there. I think this could look good, however, I’m not a big fan of layouts with lighting on in daytime situations. This may be another line to add to the ‘things to decide’ list!

In a future blog, I shall show the beginning stages of the bridge which will carry Prince’s Street over the tracks that run into the station. Every bit of construction like this is exciting and similar to getting the edge pieces in place on a jigsaw. Once the big pieces are in place, they act as a guide for everything else that follows. I’m very concious of the need to sort out things like steps to the station building and the station car park, buildings around the station end of the layout, permiter fencing, the coal yard and walls around the sidings. These will all be a part of my picture, which is slowly getting its edges completed.